- +(234) 703-2680-404

- info@oristouniversal.com

- Mon - Sat 7:00 - 18:00, Sunday - CLOSED

#3

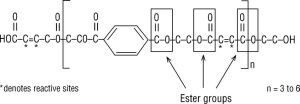

Polyester resin are unsaturated synthetic resins formed by the reaction of di-basic organic acids and polyhydric alcohols. They are used in sheets moulding and bulk casting. Wall panels fabricated from polyester resins are reinforced with fibre glass mats. This are mostly used in restaurants, kitchens, restrooms, extensive bathrooms and tubs. Polyester resin comes in different types and every batch could be factory produced depending on the nature of application or industrial work. The figure below shows the idealized chemical structure of a typical polyester. Note the positions of the ester groups (CO - O - C) and the reactive sites (C* = C*) within the molecular chain.

- Resistance to water and variety of chemicals

- Adequate resistance to weathering and ageing

- Low cost

- Polyester can withstand a temperature up to 80 degree

- It has good wetting to fibre glass

- It shrinks between of 4-8 percentage during curing

- Thermal expansion ranges from 108-200